When it comes to industrial control panels and enclosures, selecting the right material is critical. Aluminum and steel are two of the most commonly sourced options, but each brings distinct advantages and trade-offs that impact performance, durability, compliance, and overall sourcing strategy. From strength and weight to corrosion resistance and fabrication considerations, understanding these differences helps procurement teams and project managers make informed decisions that align with application requirements and long-term costs.

This blog will explore the key factors that differentiate aluminum vs steel, helping sourcing professionals evaluate the right choice for their projects.

Strength, Weight, and Structural Considerations

Aluminum and steel differ significantly in tensile strength and weight, which directly affects enclosure performance. Aluminum, for instance, is lightweight; it’s ideal for mobile equipment, transportation systems, and applications where weight reduction improves efficiency or handling.

Steel, on the other hand, offers superior rigidity and load-bearing capacity, making it a better choice for heavy-duty industrial enclosures, structural panels, and situations where durability under mechanical stress is critical. Balancing strength and weight is a key factor in material selection for any industrial project.

Corrosion Resistance and Environmental Conditions

Corrosion resistance is another major differentiator between aluminum and steel. Aluminum naturally forms a protective oxide layer, giving it inherent resistance to rust, moisture, and many outdoor environmental factors.

In contrast, steel requires coatings (such as powder coating or paint) to prevent corrosion, especially in water, wastewater, telecom, or energy applications exposed to harsh conditions. Proper material selection reduces long-term maintenance and ensures consistent performance in demanding environments.

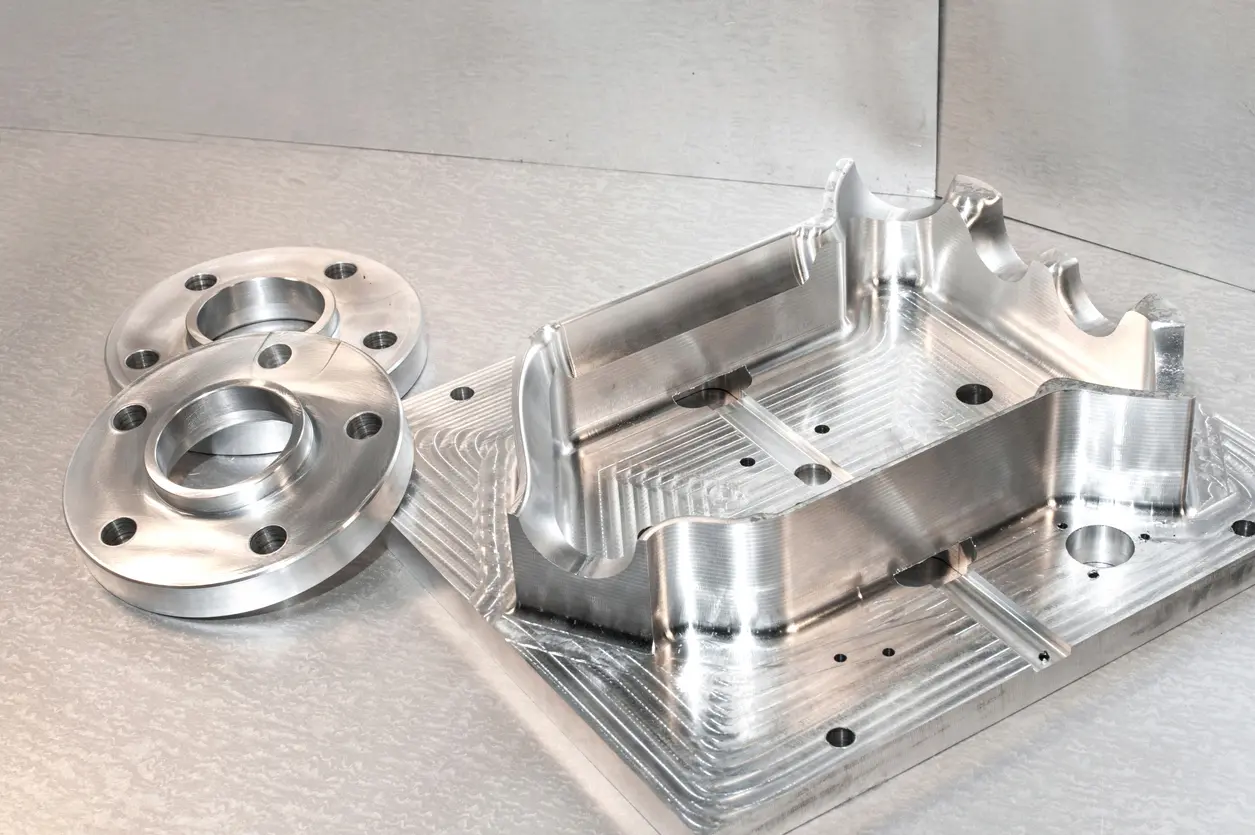

Fabrication, Coating, and Finishing Capabilities

Fabrication processes vary between aluminum and steel. Aluminum is easier to cut, bend, and machine, while steel’s rigidity can present more challenges during forming or welding. Both materials, however, benefit from finishing processes that extend service life.

Fralo’s in-house capabilities allow full-service fabrication, from precise forming and welding to UL-certified powder coating and finishing, for both aluminum and steel, ensuring consistent quality and compliance for control panels and enclosures.

Cost, Lead Time, and Total Cost of Ownership

While aluminum typically costs more per pound than steel, its lightweight properties can reduce shipping and installation expenses. Steel may offer a lower upfront material cost, but additional coating, maintenance, or corrosion protection can increase the lifecycle cost.

Availability and sourcing stability also play a role, particularly for mission-critical projects where delays are costly. Working with a U.S.-based partner like Fralo allows customers to streamline lead times, ensure compliance, and make informed material choices that balance initial costs with long-term performance and reliability.

Material Matters for Application Performance and Long-Term Value

Selecting aluminum or steel goes beyond upfront costs. Making the right choice can significantly impact maintenance, compliance, and total cost of ownership over the lifecycle of your equipment or control panel.

Need help sourcing the right enclosure or panel solution? Fralo is ISO 9001:2015 certified and provides U.S.-based fabrication with deep expertise in both materials, delivering reliable, compliant solutions that meet your project requirements. Contact us today.