In sheet metal fabrication, problems rarely originate on the production floor. They start much earlier. When material thickness, bend strategy, hardware placement, or enclosure requirements aren’t fully aligned with fabrication methods, small oversights can turn into rework, delays, or quality issues that ripple across an entire project.

That’s why effective sheet metal engineering is more than a technical discipline. It’s a sourcing and risk-management strategy. Early engineering input helps teams validate manufacturability, streamline production, and prevent issues that impact performance, compliance, and total cost of ownership.

For procurement teams, project managers, and engineers balancing budgets, timelines, and regulatory expectations, understanding how engineering influences manufacturability is essential. This blog breaks down the core benefits, and how a U.S.-based partner like Fralo supports reliable, low-risk fabrication from the start.

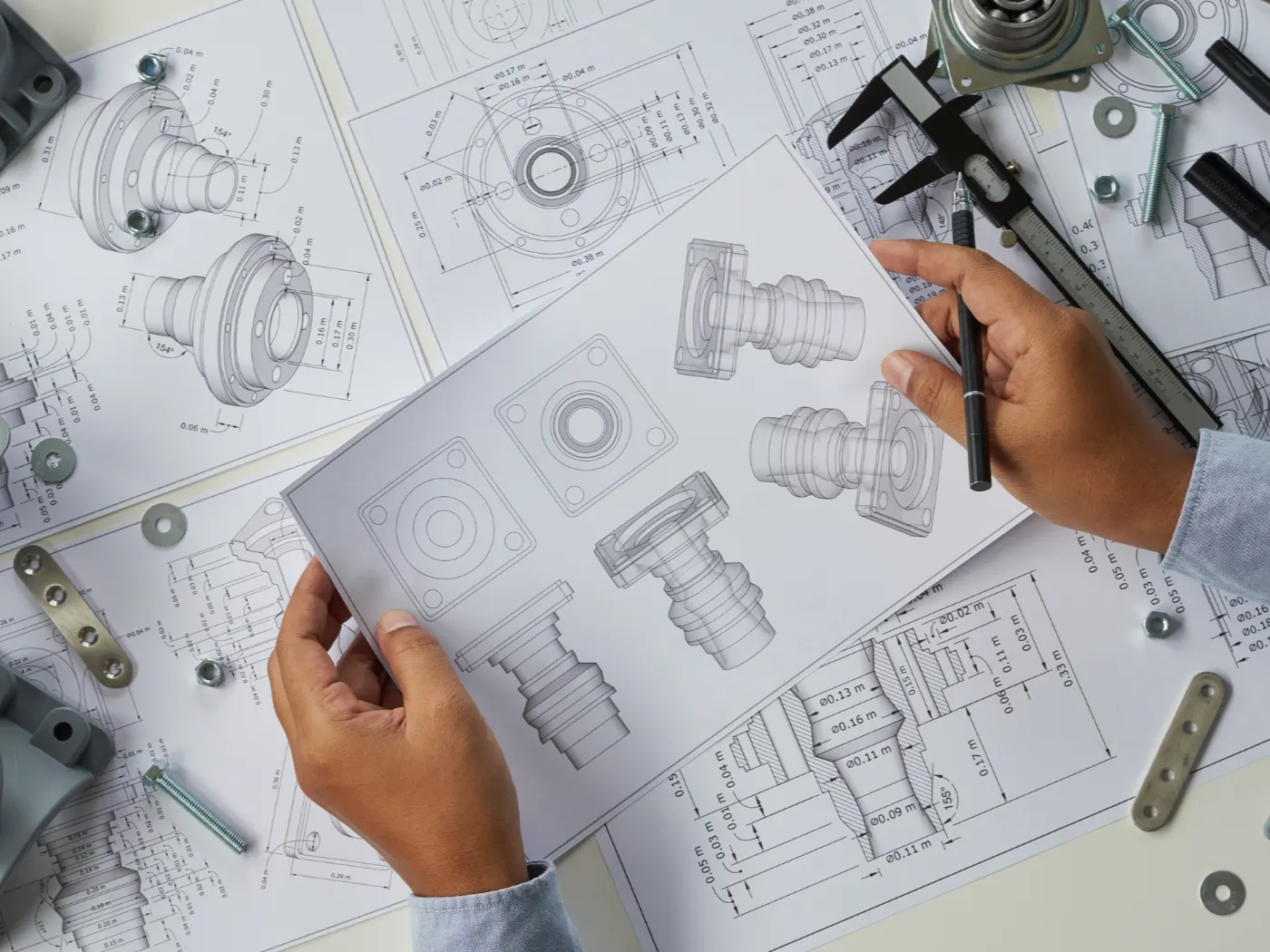

What Sheet Metal Engineering Involves — and Why It Matters

Sheet metal engineering focuses on aligning part requirements with real-world fabrication capabilities. Instead of pushing challenges downstream, engineering evaluates how every choice — from gauge and geometry to hardware and environmental exposure — affects punching, bending, welding, coating, and assembly.

In other words, effective engineering helps teams:

- Prevent issues like cracking, warping, or tolerance stack-up

- Validate whether features can be fabricated repeatably

- Ensure material behavior aligns with bending and forming requirements

- Confirm parts can move through production without unnecessary operations

In short, it connects upfront planning with downstream performance. For sourcing professionals, the result is fewer surprises, fewer change orders, and stronger predictability throughout the production lifecycle.

How Engineering Input Improves Manufacturability

Aligning Requirements With Fabrication Capabilities

Before production begins, engineering evaluates how features, material thicknesses, hardware placements, and openings will interact with CNC punching, laser cutting, forming, and welding. This step identifies potential conflicts early, long before they become floor-level problems.

Examples include tight bends that interfere with hardware, features placed too close to the edges for forming, radii that do not accommodate the chosen material, and fasteners that require revisiting bend sequences.

When fabrication constraints and part requirements align, manufacturing becomes faster, more reliable, and more cost-effective.

Reducing Complexity Without Sacrificing Performance

Not every feature adds value. In fact, unnecessary complexity is one of the most common drivers of increased cost and lead time. Engineering support helps refine parts so they maintain function but require fewer operations. This reduces the likelihood of distortion, misalignment, or scrap.

Ensuring Consistency Through Tolerance Planning

Even with perfect geometry, parts fail when tolerances aren’t planned with fabrication in mind. Sheet metal engineering accounts for bend allowances, stack-ups, material variation, and coating thickness to ensure components fit properly during assembly and perform reliably in field conditions.

Material and Thickness Choices That Impact Performance

Choosing the right material is more than selecting stainless steel, aluminum, or cold-rolled steel. Each responds differently to punching, forming, welding, and finishing, and incorrect choices can lead to production issues or long-term performance failures.

For example:

- Aluminum offers lightweight strength but requires controlled forming to prevent cracking.

- Stainless steel provides excellent corrosion resistance but demands more tonnage and careful tooling.

- Cold-rolled steel is highly manufacturable but needs proper finishing for outdoor or corrosive environments.

Gauge selection matters just as much. Too thin, and warping or deflection can occur. Too thick, and forming complexity (and cost) increases. Engineering teams help ensure material choices align with structural needs, environmental conditions, and long-term reliability.

Preventing Refabrication, Rework, and Lead Time Delays

Identifying Issues Before Production Begins

Engineering input is most valuable when it prevents expensive issues from ever reaching the floor. Common problems that upstream engineering can eliminate include:

- Features that cannot be formed without altering geometry

- Hardware interference caused by bend sequences

- Tolerances that are too tight or unnecessary

- Corner conditions that compromise coating coverage

- Material choices that complicate welding or fastening

Catching these issues early keeps production running smoothly and reduces the likelihood of costly late-stage revisions.

Engineering and Fabrication Collaboration

The most efficient projects are those where engineering and fabrication communicate from the beginning. When these teams work together, they can quickly troubleshoot challenges, refine flat patterns, optimize forming paths, and ensure every feature supports repeatable production.

This collaboration strengthens quality, reduces variability, and ensures the finished part performs as intended.

The Role of Engineering in Compliance and Quality Assurance

For many industrial applications, especially in utilities, energy, chemical processing, and telecom, compliance requirements affect how enclosures, brackets, and control systems must be constructed.

Engineering plays a direct role in supporting:

- UL 508A and UL 698A panel builds

- NEMA protection requirements

- ISO 9001:2015 process controls

- Proper gasketing, enclosures, and sealing methods

- Material and coating strategies for harsh environments

When engineering accounts for compliance early, projects avoid the risk of field failures, requalification costs, and last-minute scrambles to meet regulatory expectations.

Why Early Engineering Engagement Is a Sourcing Advantage

Engaging engineering support early, even during the quoting stage, gives procurement teams more reliable forecasts, cleaner prints, and fewer follow-up revisions that delay production.

It leads to more accurate pricing, clearer manufacturability expectations, fewer change orders, shorter lead times, and higher confidence in supplier performance. For organizations managing mission-critical equipment, this predictability is essential for meeting customer demand and protecting operational uptime.

Fralo: Your U.S.-Based Sheet Metal Engineering Partner

Sheet metal engineering isn’t just a technical step. It’s a strategic investment in efficiency, reliability, and long-term performance. When manufacturability is addressed early, teams reduce risk, strengthen quality, and keep projects on schedule.

Fralo provides U.S.-based sheet metal engineering support backed by ISO 9001:2015 certification, UL 508A/698A capabilities, and end-to-end fabrication expertise — helping OEMs and industrial customers move confidently from concept through production.

Partner with Fralo to streamline your next project and build manufacturability into every stage of the process. Ready to get started? Request a quote today.