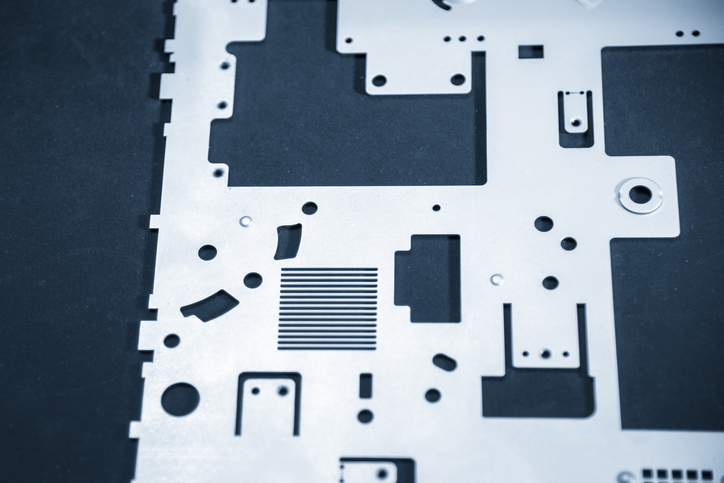

Getting the sheet metal design right before fabrication is critical to ensuring your project stays on schedule, on budget, and meets quality expectations. Yet, despite best efforts, many OEMs and sourcing teams experience common disconnects between engineering intent and manufacturing realities. These gaps in sheet metal design can lead to costly delays.

For procurement professionals and project managers responsible for vendor selection and supply chain coordination, understanding these pitfalls is essential to streamlining operations and partnering effectively with manufacturers. In this article, we’ll explore five frequent mistakes in sheet metal design, and offer practical advice on how to avoid them to improve outcomes and reduce risk.

Mistake #1: Overlooking Material Properties

Material selection is not a one-size-fits-all decision in sheet metal design. Different materials vary widely in strength, corrosion resistance, weight, and cost, all of which directly impact the performance and lifespan of the final product. For example, stainless steel offers excellent corrosion resistance for outdoor or harsh environments, while aluminum is lighter and often preferred where weight reduction matters. Choosing the wrong material can lead to premature failure, increased maintenance, or unnecessary expenses.

To avoid these issues, it’s essential to align the material choice with the specific conditions the part will face. Collaborating with your manufacturing partner to evaluate material options based on application needs helps ensure you get the right balance of durability, cost-efficiency, and manufacturability.

Mistake #2: Designing Without Manufacturing Constraints in Mind

Designs that don’t account for manufacturing realities often create costly roadblocks down the line. Factors such as bend radii, tolerances, and punch tooling limitations are critical in sheet metal design. For example, overly tight bend radii can cause cracking or warping, while unrealistic tolerances can increase scrap rates or require expensive secondary operations.

Engaging in design-for-manufacturability (DFM) collaboration with your fabrication partner early in the process helps identify and resolve potential issues before they become problems. This proactive approach reduces iteration cycles and improves overall product quality.

Mistake #3: Neglecting Fastener and Assembly Considerations

Assembly planning is often an afterthought, but it can have a significant impact on both cost and functionality. Whether your design requires welding, riveting, screws, or inserts, specifying the appropriate fastening method upfront is crucial. Late-stage changes to accommodate assembly can cause unexpected delays and increase labor costs.

Understanding how different fasteners affect strength, ease of assembly, and maintenance helps prevent costly rework. For instance, welded joints provide durability but require skilled labor, while screws or rivets allow easier disassembly but might not offer the same strength. Collaborating with manufacturers on assembly requirements during the design phase ensures a smoother production process and a better final product.

Mistake #4: Ignoring Powder Coating Requirements During Design

Powder coating is a popular finishing option for sheet metal parts due to its durability and aesthetic appeal. However, design choices can significantly influence coating quality and longevity. Areas with insufficient clearance can result in uneven coverage or buildup, which compromises corrosion resistance.

Electrical enclosures also require careful consideration of grounding and clearance to maintain safety standards after coating. Early coordination between design and finishing teams helps ensure the part meets both performance and compliance requirements.

Mistake #5: Not Accounting for Certification or Compliance Needs

In many industries, compliance with standards like UL 508A for control panels or NEMA ratings for enclosures is mandatory. Failing to factor these requirements into your design from the beginning can lead to serious issues, including project delays, increased costs, or product recalls.

Documentation and certification processes also require qualified vendors who understand the standards involved. Working with manufacturers that hold relevant certifications and have established quality systems reduces risk and ensures that products meet regulatory expectations. Early attention to compliance not only safeguards your investment but also simplifies sourcing and approval processes.

Proactive Design = Smarter Sourcing with Fralo

Avoiding common sheet metal design mistakes helps you reduce costly delays, minimize rework, and control project costs. By designing with fabrication, assembly, finishing, and compliance in mind from the start, you set your project up for smoother execution and better results.

Partnering with a U.S.-based manufacturer like Fralo ensures you have access to in-house engineering expertise, powder coating, and comprehensive sheet metal fabrication, all under one roof. This streamlined approach simplifies communication and helps you meet your project timelines with confidence.

Ready to optimize your next sheet metal project? Contact Fralo today to learn how our full-service capabilities can support your design and manufacturing needs.