Sheet Metal Punching

Fralo delivers fast, consistent sheet metal punching backed by integrated engineering, controlled workflows, and U.S.-based manufacturing.

Punching Built for Speed, Accuracy, and Production Efficiency

Sheet metal punching is a cost-effective way to produce repeatable features — especially in mid- to high-volume projects. At Fralo, our punching process is optimized for clean edges, consistent tolerances, and fast throughput, supporting a wide range of industrial and infrastructure applications. Our punching capabilities support:

✓ High-speed production for repeatable patterns and features

✓ Consistent hole and slot geometry across large production runs

✓ Cost-effective fabrication for parts requiring multiple perforations

✓ Efficient processing of steel, stainless steel, and aluminum

✓ Stable tolerances that support downstream forming, welding, and assembly

When punching is integrated early and executed precisely, teams avoid secondary machining, reduce labor, and maintain reliable part-to-part consistency.

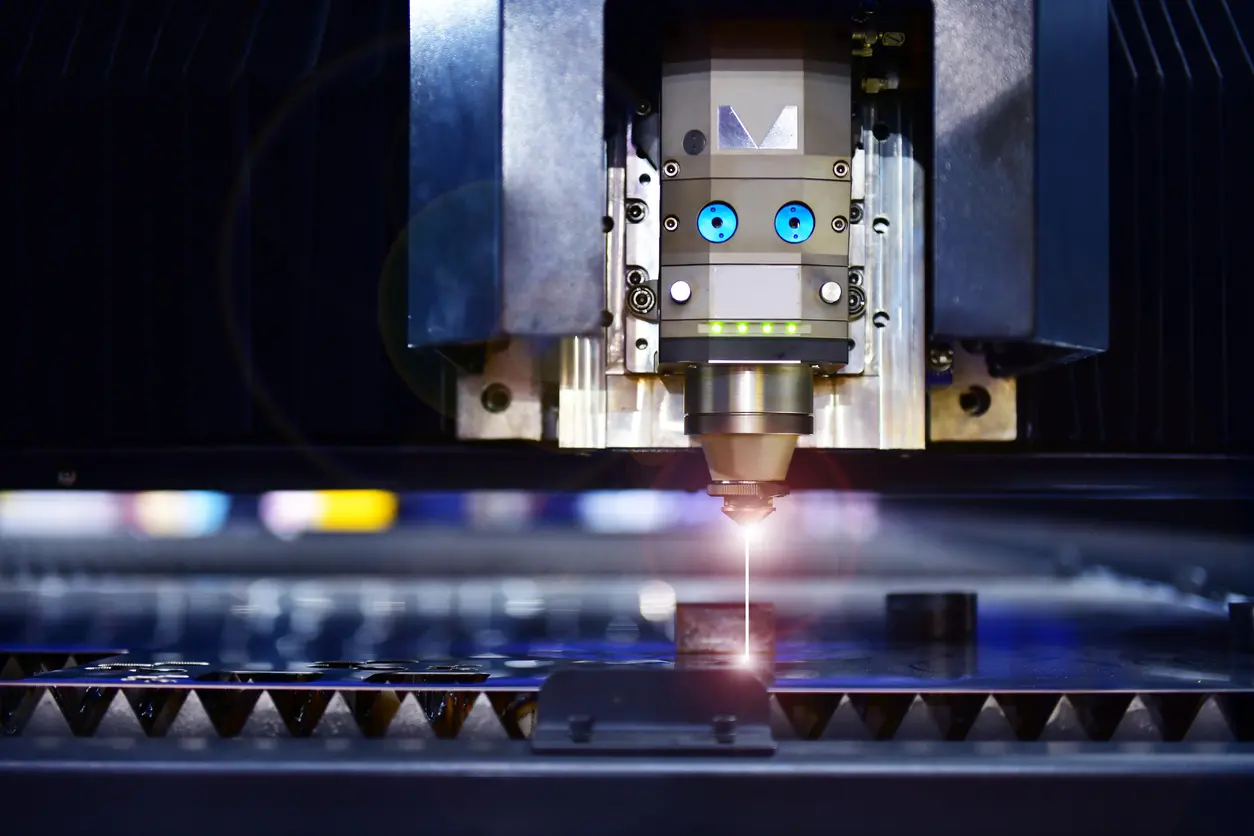

Precision Punching for Complex, Production-Ready Components

Fralo’s CNC punching systems are engineered to deliver fast, accurate, and repeatable results, helping teams reduce secondary processing, improve fit-up, and keep production moving. Clean cutouts, consistent patterns, and precise knockouts are formed in a single controlled workflow, minimizing burrs and eliminating the need for post-punch adjustments.

Because punching is fully integrated with our forming and assembly operations, every feature is produced to the correct tolerance and aligned for downstream compatibility. The result is smoother assembly, fewer production delays, and components that perform reliably in real-world conditions.

Compliance and Quality You Can Depend On

Whether you’re sourcing enclosure components, industrial brackets, or control panel elements, compliance and consistency matter. Fralo’s punch-ready parts are produced under documented, audited quality systems. We support:

✓ ISO 9001:2015 certification for consistent, traceable quality

✓ UL 508A + UL 698A expertise for control panel compatibility

✓ RoHS compliance for responsible material handling

✓ NEMA-aligned punching and feature spacing for enclosure performance

These controls ensure that punched features align with the tolerances and performance standards required in regulated environments.

Your U.S.-Based Partner for Reliable Sheet Metal Punching

Fralo’s integrated manufacturing workflow means your punched parts stay within the same facility for laser cutting, forming, welding, powder coating, and final assembly. This reduces handoffs, prevents tolerance drift, and shortens lead times, giving your project a smoother path from print to production.

Whether you’re building utility enclosures, telecom cabinets, industrial controls, or OEM assemblies, we deliver punched components that support fit, function, and long-term reliability.